Asked by Alaina Harry on Apr 24, 2024

Verified

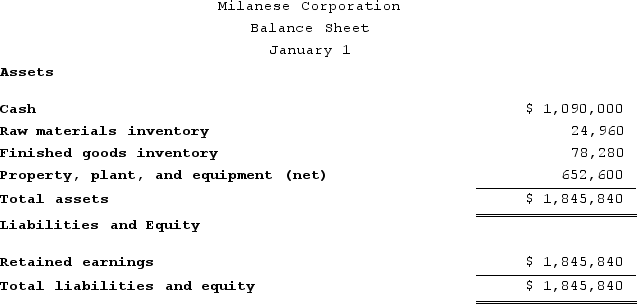

Milanese Corporation manufactures one product. It does not maintain any beginning or ending Work in Process inventories. The company uses a standard cost system in which inventories are recorded at their standard costs and any variances are closed directly to Cost of Goods Sold. There is no variable manufacturing overhead. The company's balance sheet at the beginning of the year was as follows:

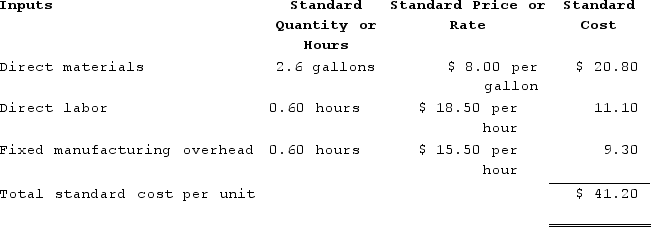

The standard cost card for the company's only product is as follows:

The standard cost card for the company's only product is as follows:

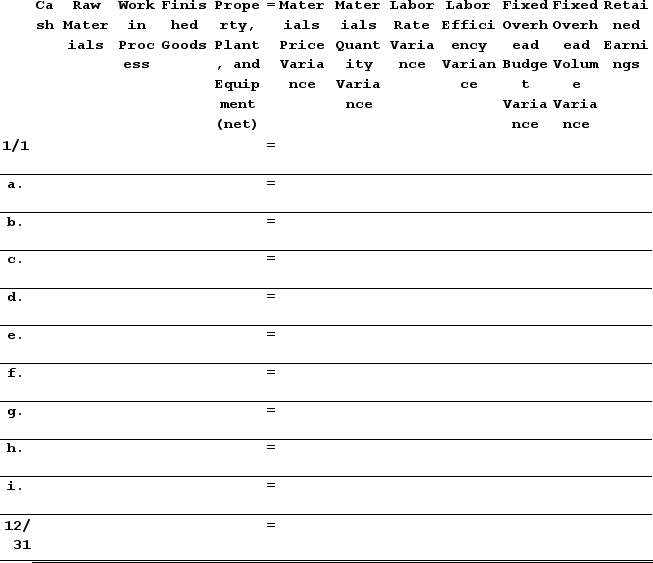

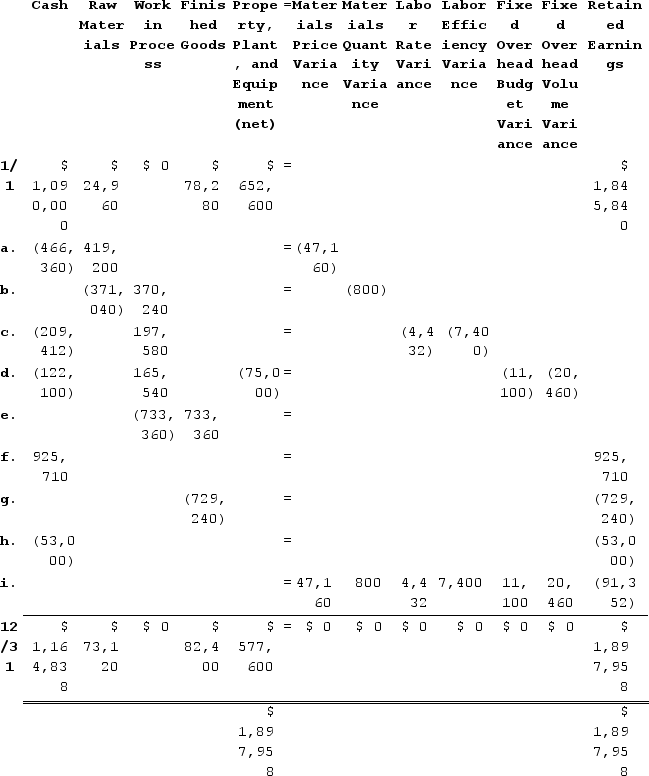

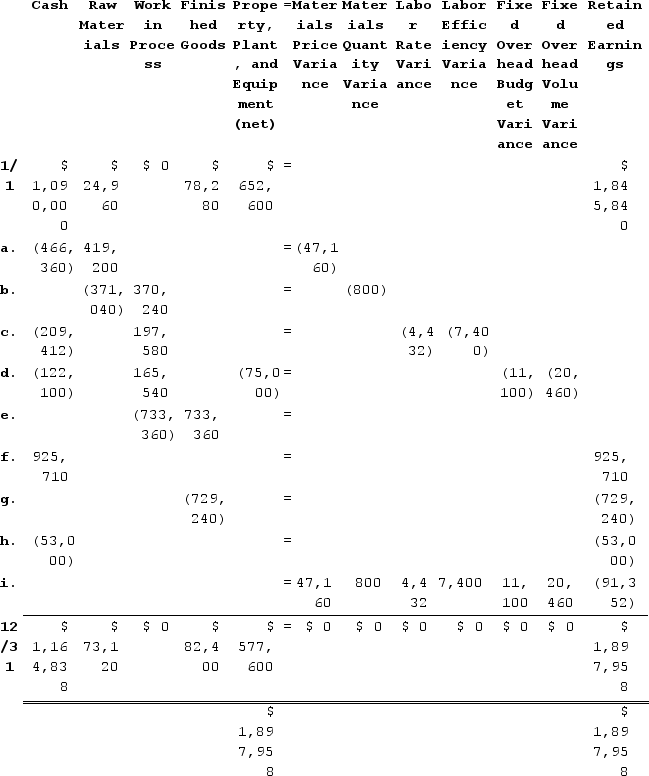

The standard fixed manufacturing overhead rate was based on budgeted fixed manufacturing overhead of $186,000 and budgeted activity of 12,000 hours.During the year, the company completed the following transactions:Purchased 52,400 gallons of raw material at a price of $8.90 per gallon.Used 46,380 gallons of the raw material to produce 17,800 units of work in process.Assigned direct labor costs to work in process. The direct labor workers (who were paid in cash) worked 11,080 hours at an average cost of $18.90 per hour.Applied fixed overhead to the 17,800 units in work in process inventory using the predetermined overhead rate multiplied by the number of direct labor-hours allowed. Actual fixed overhead costs for the year were $197,100. Of this total, $122,100 related to items such as insurance, utilities, and indirect labor salaries that were all paid in cash and $75,000 related to depreciation of manufacturing equipment.Transferred 17,800 units from work in process to finished goods.Sold for cash 17,700 units to customers at a price of $52.30 per unit.Completed and transferred the standard cost associated with the 17,700 units sold from finished goods to cost of goods sold.Paid $53,000 of selling and administrative expenses.Closed all standard cost variances to cost of goods sold.Required:1. Compute all direct materials, direct labor, and fixed overhead variances for the year.2. Enter the beginning balances and record the above transactions in the worksheet that appears below. Because of the width of the worksheet, it is in two parts. In your text, these two parts would be joined side-by-side to make one very wide worksheet.

The standard fixed manufacturing overhead rate was based on budgeted fixed manufacturing overhead of $186,000 and budgeted activity of 12,000 hours.During the year, the company completed the following transactions:Purchased 52,400 gallons of raw material at a price of $8.90 per gallon.Used 46,380 gallons of the raw material to produce 17,800 units of work in process.Assigned direct labor costs to work in process. The direct labor workers (who were paid in cash) worked 11,080 hours at an average cost of $18.90 per hour.Applied fixed overhead to the 17,800 units in work in process inventory using the predetermined overhead rate multiplied by the number of direct labor-hours allowed. Actual fixed overhead costs for the year were $197,100. Of this total, $122,100 related to items such as insurance, utilities, and indirect labor salaries that were all paid in cash and $75,000 related to depreciation of manufacturing equipment.Transferred 17,800 units from work in process to finished goods.Sold for cash 17,700 units to customers at a price of $52.30 per unit.Completed and transferred the standard cost associated with the 17,700 units sold from finished goods to cost of goods sold.Paid $53,000 of selling and administrative expenses.Closed all standard cost variances to cost of goods sold.Required:1. Compute all direct materials, direct labor, and fixed overhead variances for the year.2. Enter the beginning balances and record the above transactions in the worksheet that appears below. Because of the width of the worksheet, it is in two parts. In your text, these two parts would be joined side-by-side to make one very wide worksheet.

3. Determine the ending balance (e.g., 12/31 balance) in each account.

3. Determine the ending balance (e.g., 12/31 balance) in each account.

Budgeted Fixed Manufacturing Overhead

This term refers to the projected fixed costs associated with the production process, including expenses that do not change with the level of production.

Standard Fixed Manufacturing Overhead Rate

A predetermined rate used in costing to allocate the estimated fixed manufacturing overhead costs to individual units of production based on a consistent activity base, such as machine hours or labor hours.

Budgeted Activity

The planned level of output or operation used in the budgeting process, often serving as the basis for allocating fixed costs.

- Acquire knowledge on accurately documenting transactions within a standard costing framework.

- Acquire the competency to calculate discrepancies between real expenses and benchmark costs, covering variances in direct materials, direct labor, and fixed overheads.

- Comprehend the method of transferring standard cost variances into the Cost of Goods Sold.

Verified Answer

DS

Dinesh Sapkota6 days ago

Final Answer :

1.Materials price variance = Actual quantity × (Actual price − Standard price)= 52,400 gallons × ($8.90 per gallon − $8.00 per gallon)= 52,400 gallons × ($0.90 per gallon)= $47,160 UnfavorableMaterials quantity variance:Standard quantity = Actual output × Standard quantity = 17,800 units × 2.6 gallons per unit = 46,280 gallonsMaterials quantity variance = (Actual quantity − Standard quantity) × Standard price= (46,380 gallons − 46,280 gallons) × $8.00 per gallon= (100 gallons) × $8.00 per gallon= $800 UnfavorableLabor rate variance = Actual hours × (Actual rate − Standard rate)= 11,080 hours × ($18.90 per hour − $18.50 per hour)= 11,080 hours × ($0.40 per hour)= $4,432 UnfavorableLabor efficiency variance:Standard hours = Actual output × Standard quantity = 17,800 units × 0.60 hours per unit = 10,680 hoursLabor efficiency variance = (Actual hours − Standard hours) × Standard rate= (11,080 hours − 10,680 hours) × $18.50 per hour= (400 hours) × $18.50 per hour= $7,400 UnfavorableBudget variance = Actual fixed overhead − Budgeted fixed overhead= $197,100 − $186,000= $11,100 UnfavorableVolume variance = Budgeted fixed overhead − Fixed overhead applied to work in process= $186,000 − (10,680 hours × $15.50 per hour)= $186,000 − ($165,540)= $20,460 Unfavorable2. & 3.

The explanations for transactions a through i are as follows:Cash decreases by the actual cost of the raw materials purchased, which is Actual quantity × Actual price = 52,400 gallons × $8.90 per gallon = $466,360. Raw Materials increase by the standard cost of the raw materials purchased, which is Actual quantity × Standard price = 52,400 gallons × $8.00 per gallon = $419,200. The materials price variance is $47,160 Unfavorable.Raw Materials decrease by the standard cost of the raw materials used in production, which is Actual quantity × Standard price = 46,380 gallons × $8.00 per gallon = $371,040. Work in Process increases by the standard cost of the standard quantity of raw materials allowed for the actual output, which is Standard quantity × Standard price = (17,800 units × 2.6 gallons per unit) × $8.00 per gallon = 46,280 gallons × $8.00 per gallon = $370,240. The difference is the Materials Quantity Variance which is $800 Unfavorable.Cash decreases by the actual amount paid to direct laborers, which is Actual hours × Actual rate = 11,080 hours × $18.90 per hour = $209,412. Work in Process increases by the standard cost of the standard amount of hours allowed for the actual output, which is Standard hours × Standard rate = (17,800 units × 0.60 hours per unit) × $18.50 per hour = 10,680 hours × $18.50 per hour = $197,580. The difference consists of the Labor Rate Variance which is $4,432 Unfavorable and the Labor Efficiency Variance which is $7,400 Unfavorable.Cash decreases by the actual amount paid for various fixed overhead costs, which is $122,100. Work in Process increases by the standard amount of hours allowed for the actual output multiplied by the predetermined overhead rate, which is (17,800 units × 0.60 hours per unit) × $15.50 per hour = 10,680 hours × $15.50 per hour = $165,540. Property, Plant, and Equipment (net) decreases by the amount of depreciation for the period, which is $75,000. The difference is the Fixed Overhead (FOH) Budget Variance which is $11,100 Unfavorable and the Fixed Overhead (FOH) Volume Variance which is $20,460 Unfavorable.Work in Process decreases by the number of units transferred to Finished Goods multiplied by the standard cost per unit = 17,800 units × $41.20 per unit = $733,360. Finished Goods increases by the same amount.Cash increases by the number of units sold multiplied by the selling price per unit, which is 17,700 units × $52.30 per unit = $925,710. Retained Earnings increases by the same amount.Finished Goods decreases by the number of units sold multiplied by their standard cost per unit, which is 17,700 units × $41.20 per unit = $729,240. Retained Earnings decreases by the same amount.Cash and Retained Earnings decrease by $53,000 to record the selling and administrative expenses.All variance accounts take their balance to zero and they are closed to Cost of Goods Sold (which resides within Retained Earnings).

The explanations for transactions a through i are as follows:Cash decreases by the actual cost of the raw materials purchased, which is Actual quantity × Actual price = 52,400 gallons × $8.90 per gallon = $466,360. Raw Materials increase by the standard cost of the raw materials purchased, which is Actual quantity × Standard price = 52,400 gallons × $8.00 per gallon = $419,200. The materials price variance is $47,160 Unfavorable.Raw Materials decrease by the standard cost of the raw materials used in production, which is Actual quantity × Standard price = 46,380 gallons × $8.00 per gallon = $371,040. Work in Process increases by the standard cost of the standard quantity of raw materials allowed for the actual output, which is Standard quantity × Standard price = (17,800 units × 2.6 gallons per unit) × $8.00 per gallon = 46,280 gallons × $8.00 per gallon = $370,240. The difference is the Materials Quantity Variance which is $800 Unfavorable.Cash decreases by the actual amount paid to direct laborers, which is Actual hours × Actual rate = 11,080 hours × $18.90 per hour = $209,412. Work in Process increases by the standard cost of the standard amount of hours allowed for the actual output, which is Standard hours × Standard rate = (17,800 units × 0.60 hours per unit) × $18.50 per hour = 10,680 hours × $18.50 per hour = $197,580. The difference consists of the Labor Rate Variance which is $4,432 Unfavorable and the Labor Efficiency Variance which is $7,400 Unfavorable.Cash decreases by the actual amount paid for various fixed overhead costs, which is $122,100. Work in Process increases by the standard amount of hours allowed for the actual output multiplied by the predetermined overhead rate, which is (17,800 units × 0.60 hours per unit) × $15.50 per hour = 10,680 hours × $15.50 per hour = $165,540. Property, Plant, and Equipment (net) decreases by the amount of depreciation for the period, which is $75,000. The difference is the Fixed Overhead (FOH) Budget Variance which is $11,100 Unfavorable and the Fixed Overhead (FOH) Volume Variance which is $20,460 Unfavorable.Work in Process decreases by the number of units transferred to Finished Goods multiplied by the standard cost per unit = 17,800 units × $41.20 per unit = $733,360. Finished Goods increases by the same amount.Cash increases by the number of units sold multiplied by the selling price per unit, which is 17,700 units × $52.30 per unit = $925,710. Retained Earnings increases by the same amount.Finished Goods decreases by the number of units sold multiplied by their standard cost per unit, which is 17,700 units × $41.20 per unit = $729,240. Retained Earnings decreases by the same amount.Cash and Retained Earnings decrease by $53,000 to record the selling and administrative expenses.All variance accounts take their balance to zero and they are closed to Cost of Goods Sold (which resides within Retained Earnings).

The explanations for transactions a through i are as follows:Cash decreases by the actual cost of the raw materials purchased, which is Actual quantity × Actual price = 52,400 gallons × $8.90 per gallon = $466,360. Raw Materials increase by the standard cost of the raw materials purchased, which is Actual quantity × Standard price = 52,400 gallons × $8.00 per gallon = $419,200. The materials price variance is $47,160 Unfavorable.Raw Materials decrease by the standard cost of the raw materials used in production, which is Actual quantity × Standard price = 46,380 gallons × $8.00 per gallon = $371,040. Work in Process increases by the standard cost of the standard quantity of raw materials allowed for the actual output, which is Standard quantity × Standard price = (17,800 units × 2.6 gallons per unit) × $8.00 per gallon = 46,280 gallons × $8.00 per gallon = $370,240. The difference is the Materials Quantity Variance which is $800 Unfavorable.Cash decreases by the actual amount paid to direct laborers, which is Actual hours × Actual rate = 11,080 hours × $18.90 per hour = $209,412. Work in Process increases by the standard cost of the standard amount of hours allowed for the actual output, which is Standard hours × Standard rate = (17,800 units × 0.60 hours per unit) × $18.50 per hour = 10,680 hours × $18.50 per hour = $197,580. The difference consists of the Labor Rate Variance which is $4,432 Unfavorable and the Labor Efficiency Variance which is $7,400 Unfavorable.Cash decreases by the actual amount paid for various fixed overhead costs, which is $122,100. Work in Process increases by the standard amount of hours allowed for the actual output multiplied by the predetermined overhead rate, which is (17,800 units × 0.60 hours per unit) × $15.50 per hour = 10,680 hours × $15.50 per hour = $165,540. Property, Plant, and Equipment (net) decreases by the amount of depreciation for the period, which is $75,000. The difference is the Fixed Overhead (FOH) Budget Variance which is $11,100 Unfavorable and the Fixed Overhead (FOH) Volume Variance which is $20,460 Unfavorable.Work in Process decreases by the number of units transferred to Finished Goods multiplied by the standard cost per unit = 17,800 units × $41.20 per unit = $733,360. Finished Goods increases by the same amount.Cash increases by the number of units sold multiplied by the selling price per unit, which is 17,700 units × $52.30 per unit = $925,710. Retained Earnings increases by the same amount.Finished Goods decreases by the number of units sold multiplied by their standard cost per unit, which is 17,700 units × $41.20 per unit = $729,240. Retained Earnings decreases by the same amount.Cash and Retained Earnings decrease by $53,000 to record the selling and administrative expenses.All variance accounts take their balance to zero and they are closed to Cost of Goods Sold (which resides within Retained Earnings).

The explanations for transactions a through i are as follows:Cash decreases by the actual cost of the raw materials purchased, which is Actual quantity × Actual price = 52,400 gallons × $8.90 per gallon = $466,360. Raw Materials increase by the standard cost of the raw materials purchased, which is Actual quantity × Standard price = 52,400 gallons × $8.00 per gallon = $419,200. The materials price variance is $47,160 Unfavorable.Raw Materials decrease by the standard cost of the raw materials used in production, which is Actual quantity × Standard price = 46,380 gallons × $8.00 per gallon = $371,040. Work in Process increases by the standard cost of the standard quantity of raw materials allowed for the actual output, which is Standard quantity × Standard price = (17,800 units × 2.6 gallons per unit) × $8.00 per gallon = 46,280 gallons × $8.00 per gallon = $370,240. The difference is the Materials Quantity Variance which is $800 Unfavorable.Cash decreases by the actual amount paid to direct laborers, which is Actual hours × Actual rate = 11,080 hours × $18.90 per hour = $209,412. Work in Process increases by the standard cost of the standard amount of hours allowed for the actual output, which is Standard hours × Standard rate = (17,800 units × 0.60 hours per unit) × $18.50 per hour = 10,680 hours × $18.50 per hour = $197,580. The difference consists of the Labor Rate Variance which is $4,432 Unfavorable and the Labor Efficiency Variance which is $7,400 Unfavorable.Cash decreases by the actual amount paid for various fixed overhead costs, which is $122,100. Work in Process increases by the standard amount of hours allowed for the actual output multiplied by the predetermined overhead rate, which is (17,800 units × 0.60 hours per unit) × $15.50 per hour = 10,680 hours × $15.50 per hour = $165,540. Property, Plant, and Equipment (net) decreases by the amount of depreciation for the period, which is $75,000. The difference is the Fixed Overhead (FOH) Budget Variance which is $11,100 Unfavorable and the Fixed Overhead (FOH) Volume Variance which is $20,460 Unfavorable.Work in Process decreases by the number of units transferred to Finished Goods multiplied by the standard cost per unit = 17,800 units × $41.20 per unit = $733,360. Finished Goods increases by the same amount.Cash increases by the number of units sold multiplied by the selling price per unit, which is 17,700 units × $52.30 per unit = $925,710. Retained Earnings increases by the same amount.Finished Goods decreases by the number of units sold multiplied by their standard cost per unit, which is 17,700 units × $41.20 per unit = $729,240. Retained Earnings decreases by the same amount.Cash and Retained Earnings decrease by $53,000 to record the selling and administrative expenses.All variance accounts take their balance to zero and they are closed to Cost of Goods Sold (which resides within Retained Earnings).

Learning Objectives

- Acquire knowledge on accurately documenting transactions within a standard costing framework.

- Acquire the competency to calculate discrepancies between real expenses and benchmark costs, covering variances in direct materials, direct labor, and fixed overheads.

- Comprehend the method of transferring standard cost variances into the Cost of Goods Sold.